- A6

-

Magnetic chuck

Magnetic chuck

Magnetic chuck

Magnetic chuck

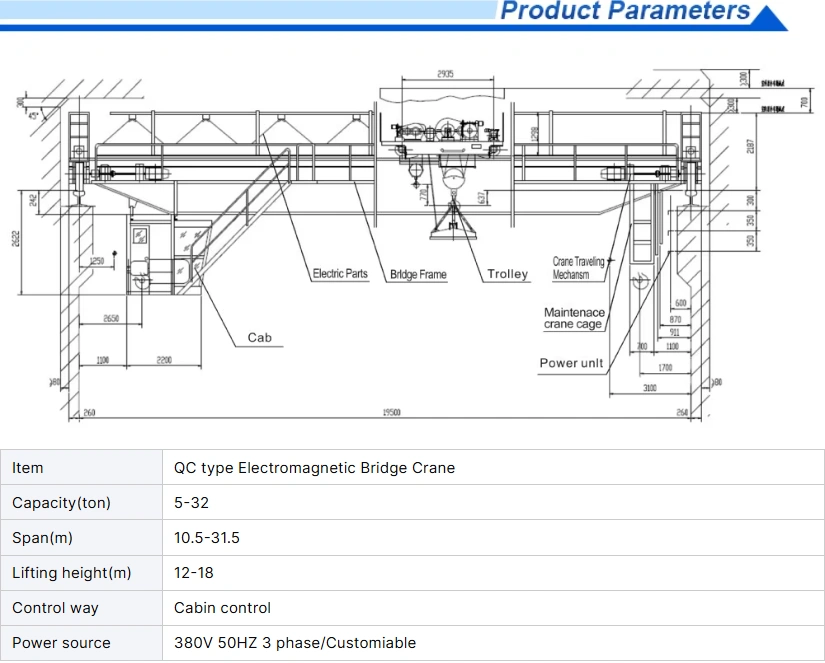

The electric double girder crane consists of four main parts: the bridge, trolley, hoist mechanism, and electrical equipment. It is ideal for various settings, such as stations, ports, factories, and warehouses. For different environments and uses, different types of cranes are available, including slow-speed, explosion-proof, electromagnetic, and insulated models.

For example, the double girder gantry crane is used in outdoor areas and warehouses for loading and unloading materials, while the electric hoist double girder crane is suited for low buildings to lift materials.

Magnet Double Girder Overhead Crane – Key Advantages & Features

1. Versatile Walkway Door Directions for Easy Access

Flexible entry options: Control room can be accessed from the end, side, or top walkway doors, making operation and maintenance easier.

2. High Lifting Capacity with Integrated Electromagnetic Disk

Heavy-duty performance: Lifting capacity includes the weight of the electromagnetic disk, increasing efficiency in material handling.

Secure operation: The rotary part of the electromagnetic hook is locked with screws to prevent rotation, ensuring safe use.

3. Robust Slewing Carrier-Beam for Precise Load Handling

Stable design: Offers superior stability and anti-swing properties for safe lifting.

Horizontal rotation: Ideal for handling steel plates, profiles, spools, and irregular materials.

4. Wide Application Across Industries

Perfect for both indoor and outdoor use in:

Steel mills 🏭

Shipyards ⚓

Ports & storage yards 🏗️

Warehouses & factories 🏢

Compatible with various lifting tools: Magnetic chucks, tongs, and other specialized attachments.

5. Multiple Operating Modes for Flexible Control

Available control options:

Pendant controller (push-button)

Remote control (wireless operation)

Cabin control (joystick for precision handling)

6. Customizable for Hazardous Environments

Explosion-proof & acid-resistant options available for tough industrial conditions.

7. End-to-End Support & Certification Compliance

Expert installation & training: Our engineers offer on-site guidance for setup and operation.

Global certifications:

CE, SGS, TÜV, BV, CU-TR (product compliance)

ISO 9001, ISO 14001, ISO 28001 (quality, environmental, and safety standards)

Why Choose Our Magnet Double Girder Overhead Crane? ✅

✔ Heavy-duty lifting with electromagnetic efficiency

✔ Versatile for industries like steel, shipping, and logistics

✔ High safety & stability with anti-swing beam

✔ Custom control options (remote, pendant, cabin)

✔ Certified & compliant with global standards

Additional Features

Our Magnet Double Girder Overhead Crane is equipped with a removable electromagnetic chunk, ideal for lifting magnetic materials like steel, pig iron, and other black metal products. It is widely used in:

Iron and steel enterprises’ rolling lines

Finished-parts storage yards

Steel storage yards in shipyards

Cutting stock workshops

The crane’s lifting capacity includes the weight of the electromagnetic chunk, excluding the total weight of the crane.

The double girder electromagnetic overhead crane is a highly efficient solution for lifting steel and ferrous materials. It uses an electromagnetic lifting system to make transporting heavy iron-based loads easier and more precise in industrial environments.

Key Working Principle:

Electromagnetic Operation: When powered, the crane’s magnet generates a strong magnetic field to lift steel products securely.

Controlled Release: Once the power is off, the magnetic force releases, allowing safe placement of the load.

Ideal Applications & Industries

Steel & Metallurgical Plants

Lifting steel billets, slabs, and coils in rolling mills and foundries.

Moving scrap iron for recycling and melting.

Loading/unloading steel bars and profiles on production lines.

Shipbuilding & Heavy Machinery Manufacturing

Lifting large steel plates for hull construction.

Moving heavy metal components during assembly.

Ports & Logistics Yards

Efficiently stacking steel coils in storage.

Quick loading/unloading of iron materials from ships and trucks.

Scrap Recycling & Waste Management

Sorting and transporting scrap metal in recycling facilities.

Handling bulky iron waste in junkyards and processing plants.

Warehousing & Fabrication Shops

Organizing steel inventory in warehouses.

Feeding raw materials into CNC machines and fabrication units.

Why Choose Our Electromagnetic Overhead Crane?

✔ Fast & Efficient – No need for slings or clamps; instant magnetic lifting.

✔ High Precision – Smooth handling of steel plates, coils, and irregular shapes.

✔ Heavy-Duty Capacity – Can lift tons of weight with ease.

✔ Minimal Manual Labor – Reduces worker fatigue and injury risks.

This crane is perfect for industries dealing with large-scale steel handling. It ensures speed, safety, and improved productivity in material movement.

Wechat:

+86 16627702870