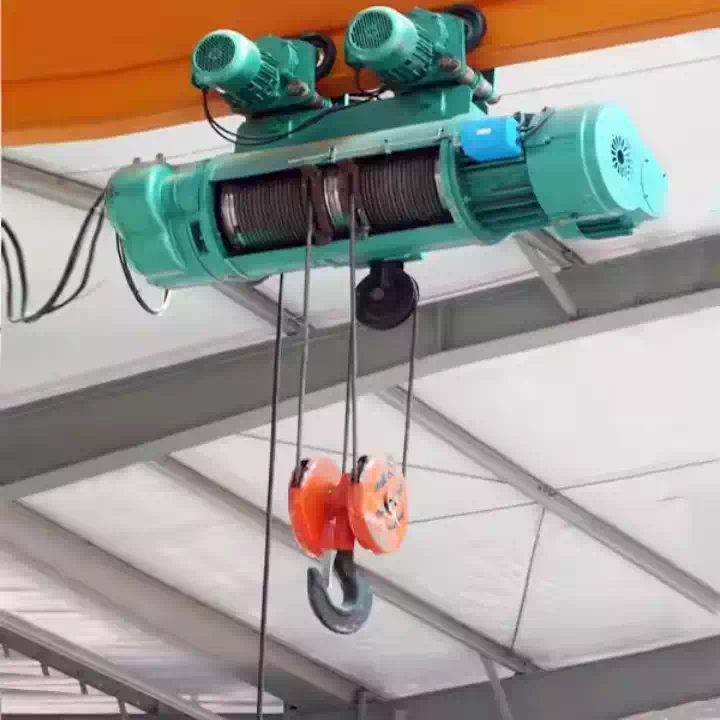

Dual-Purpose Overhead Crane with Grab and Magnet

A dual-purpose overhead crane combines both a grab bucket and a magnet, designed for efficient material handling. It allows for both grabbing and magnetic lifting in one crane.

Applications of Overhead Bridge Traveling Crane

The Overhead Bridge Traveling Crane is commonly used in mines, ports, factories, workshops, warehouses, and storage yards. It is ideal for transporting, assembling, loading, and unloading bulk materials.

Why Choose Our Dual-Purpose Bridge Crane?

✅ 2-in-1 Functionality – No need for multiple cranes.

✅ Heavy-Duty Performance – Easily handles scrap, steel, and bulk materials.

✅ Safety Engineering – Meets international standards for industrial lifting.

✅ Custom Solutions – Designed to suit your facility’s temperature, power, and load needs.

Applications

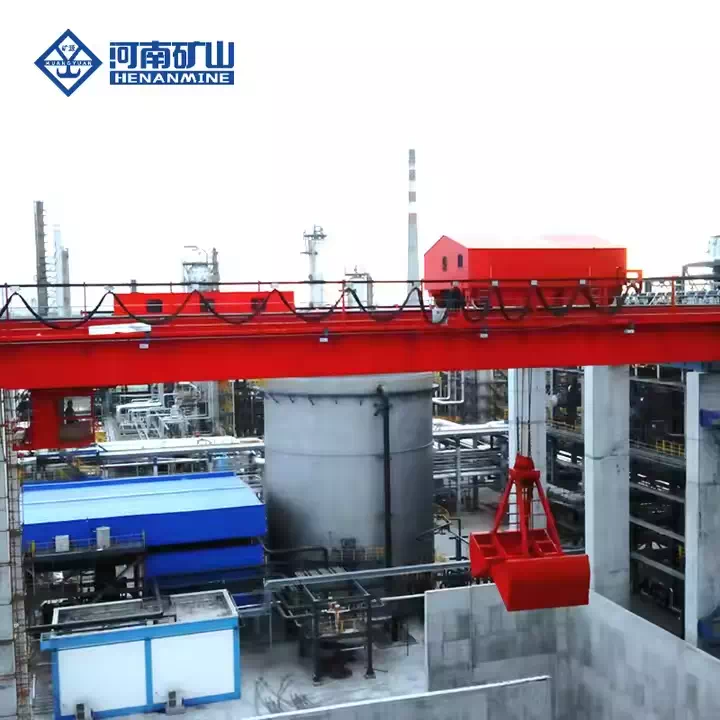

The crane is widely used in steel mills, mines, ports, warehouses, and other places for handling bulk materials, scrap steel, steel plates, and steel billets. For example, in steel mills, it moves scrap steel and iron ore. In ports, it loads and unloads bulk cargo and containers. In warehouses, it moves various metal products and steel materials.

Grab bucket

Grab bucket

Magnetic chuck

Magnetic chuck