- A6

-

Lifting hook

Lifting hook

Lifting hook

Lifting hook

Insulation Double Girder Overhead Crane – Key Advantages & Features

1. Enhanced Safety with Multiple Insulation Layers

The crane is designed with multiple insulation structures to minimize the risk of accidents. This ensures effective electrical isolation and operator safety, especially in hazardous environments like metal smelting workshops.

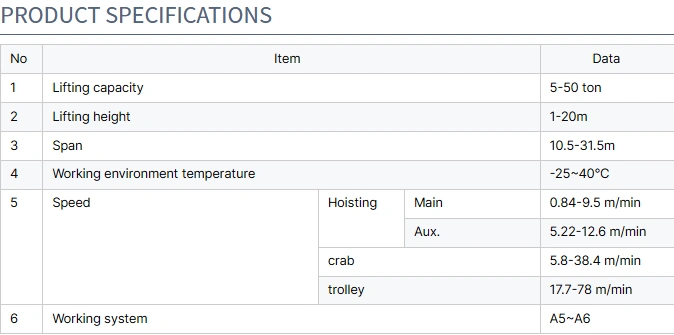

The crane offers a lifting capacity range from 5t to 320t, with a span range of 10.5m to 40m and a lifting height range of 10m to 24m. The work grade is available in A6, A7, and A8.

2. Strong Construction & Durability

The crane is built with a double welded box girder, providing exceptional load-bearing capacity. It uses high-strength materials like Q235B/Q345B steel, 16Mn trolley rails, and epoxy zinc-rich paint (120μm) for corrosion resistance.

The main girder and end beams are connected with high-strength bolts for structural integrity.

3. Designed for Extreme Industrial Environments

The insulation overhead crane is ideal for use in electrolysis workshops handling metals like aluminum, magnesium, lead, zinc, and copper, offering insulation against strong electrical currents.

The crane is fully equipped with the following components:

Bridge frame, trolley assemblies, crane assemblies, bridge running mechanism

Work platforms, cabins, electrical rooms

Full electrical and control systems, power supply systems

Insulation detection devices

Remote maintenance system (monitors crane operation data, insulation levels, fault conditions, with self-repair software and hardware systems)

Audible/visual alarm systems, full safety protection systems.

In production environments with high humidity and acidic mist, electrical parts and the cabin are sealed to IP55 protection levels. The cabin features corrosion-resistant industrial air conditioning (cooling and heating).

4. Customizable for Your Needs

Adaptable to lifting capacity, span, height, power supply, and workshop conditions. The crane is available with optional features like rails, pendant/remote/cabin control methods, and insulation upgrades.

It can also be equipped with special components for handling high-temperature molten salts, large currents, strong magnetic fields, dust, and hydrogen fluoride gas.

5. Advanced Control & Flexible Operation

Pendant control (36V): IP65-rated, 500,000+ operation cycles, emergency stop.

Wireless remote (24V): 100m range, interference-free, joystick/button options.

Cabin control: Ergonomic seat, panoramic view, air-conditioned, with a master controller for precision.

6. Comprehensive Safety Protections

Overload protection: Auto-shutoff (allows only lowering motion).

Anti-collision: Limit switches + wireless sensors.

Includes emergency stop, anti-falling motor brakes, audible/visual alarms, and rain covers for outdoor use.

Voltage/current protections and safety hook latches to prevent load slippage.

7. Low Maintenance & Long Lifespan

Polyurethane buffers and anti-friction bearings reduce wear.

Walkway with handrails (1050mm) and flower-pattern plates for easy inspection.

8. Reliable After-Sales Support

1-year warranty + lifetime cost-price spare parts.

Global service network for troubleshooting and upgrades.

Why Choose Our Insulation Overhead Crane?

✔ Built for hazardous environments (foundries, smelting, chemical plants).

✔ FEM/DIN-compliant, heavy-duty (A6–A8) work grade.

✔ Custom insulation solutions tailored to meet industry-specific safety standards.

✔ Competitive pricing without sacrificing quality or safety.

Application Scenarios of Insulation Double Girder Overhead Crane

The QY Insulation Double Girder Overhead Crane is designed for hazardous environments where electrical insulation is crucial for operator safety and equipment reliability. Its primary applications include:

1. Aluminum & Magnesium Smelting Factories

Safely handles molten aluminum and magnesium in high-temperature electrolysis processes.

Prevents electrical conduction from charged equipment to the crane structure.

2. Non-Ferrous Metal Electrolysis Workshops

Ideal for refining copper, zinc, and lead, where stray currents can be dangerous.

Insulated hook and lifting system ensure zero current leakage.

3. High-Temperature Metallurgy Plants

Resists extreme heat in foundries and casting workshops.

Epoxy-phenolic laminate insulation ensures stability under thermal stress.

4. Chemical & Corrosive Environments

Protected with anti-corrosive paint (120μm epoxy zinc-rich coating).

Suitable for acid and alkali-heavy industries like battery manufacturing.

5. Outdoor Heavy-Duty Lifting

Rain covers and IP65-rated controls for all-weather operation.

Used in scrap metal yards, ports, and power plants.

Why It Fits These Industries

✔ Triple insulation meets ≥1MΩ resistance standards (20–25°C, ≤85% humidity).

✔ Heavy-duty FEM/DIN design for A6–A8 work grades.

✔ Customizable for specific voltage, span, and load requirements.

✔ Designed for environments with temperatures between -10°C and 60°C.

✔ Works in non-flammable, non-explosive gas environments.

✔ Can adapt to high-temperature molten salts, large currents, strong magnetic fields, dust, and corrosive conditions.

✔ Lifting parts exposed to radiant heat will not exceed 300°C.

Special Material Requirements

The insulation materials used, such as insulation plates, tubes, and rods, must meet the crane's insulation standards.

For cranes operating in strong magnetic fields, anti-magnetic materials must be used in parts where the hook may be affected. The material's mechanical properties must not be less than 1Cr18Ni9Ti.

Parts exposed to high-temperature solutions must have sufficient high-temperature resistance to prevent melting.

Wechat:

+86 16627702870