- A6

-

Grab bucket

Grab bucket

Grab bucket

Grab bucket

QZ Double Girder Grab Crane Features:

The crane is designed to work in environments from -20°C to +40°C with relative humidity up to 85%. It is not suitable for explosive or corrosive atmospheres.

Common applications include power plants, cargo yards, factories, and docks for bulk material handling.

Equipped with a PLC-based control system for energy-efficient, quick operation.

Capacity: The crane’s load includes the grab's weight.

Grab Functionality: Available in parallel or vertical configurations, with four-wire rope grabs for easy handling.

Versatile Material Handling

Precise Operations: Control the grab's opening and closing with high accuracy, perfect for industries like metallurgy, cement, and chemical production.

Work Efficiency: High-speed lifting and placement ensure minimal material spill.

Safety and Efficiency Benefits

Built-In Safety: Reduces the need for manual labor in hazardous conditions.

Remote Control Features: Allows for operation without on-site personnel.

Applications

The QZ Double Girder Grab Crane is ideal for bulk material transport in various environments, including construction, docks, and factories.

Environmental Adaptability: Can be used indoors or outdoors with additional weather protection if necessary.

Grab Double Girder Overhead Crane – Key Advantages & Features

1. Customized and Smart Design for Modern Industry

Tailored Solutions: Custom-built to meet your capacity and green industry needs.

Smart Automation: Features PLC control, precise positioning, and anti-sway for smooth, efficient operations.

2. Built for Tough Environments

Heavy-Duty Box Girder Structure: With high fatigue resistance, it's ideal for extreme conditions like heat, humidity, and fog.

Reliable Grab Mechanism: The crane includes a switching mechanism for the grab and a lifting system for smooth, balanced handling of materials.

3. Advanced Automation & Remote Control

Fog-Proof Intelligence: Operates effortlessly in low-visibility, performing auto-grabbing, placement, and transport with no manual input.

Remote Operation: Control the crane remotely, saving on labor costs and enhancing safety.

4. Efficient & Flexible Material Handling

Clamshell Grab: Perfect for bulk materials such as coal, gravel, and scrap, with fast loading and unloading.

Compatibility with Hook Cranes: Uses similar components to standard bridge cranes, making maintenance and integration easy.

5. Enhanced Productivity & Safety

Precision Control: Prevents material spills and downtime.

Safety: Reduces manual labor in dangerous settings.

Why Choose Our Grab Double Girder Overhead Crane?

Smart Design: IoT-enabled and automation-ready.

Built for Extreme Conditions: Works in heat, humidity, and fog.

Lower Operational Costs: Managed remotely.

Faster ROI: Efficient and high-capacity material handling.

The QZ Grab Double Girder Overhead Crane is designed to handle bulk materials like coal, ore, slag, sand, and construction waste. It uses a four-rope grab bucket and heavy-duty dual girders for stable, high-capacity lifting. The system supports both cabin operation and remote control. Suitable for indoor and outdoor use, even in hot, humid, and dusty conditions.

Scrap Metal: Quickly lifts scrap steel, iron, and recycled metals.

Blast Furnace Feeding: Moves coal, coke, and ore for steel production.

Slag Removal: Clears molten slag after processing.

🛠 Used in Guangxi Yiji Steel's 10-million-ton green冶金基地 for clean, automated upgrading.

Coal & Grain: Loads and unloads coal, wheat, soybeans from ships or trucks.

Construction Materials: Transfers sand, gravel, and minerals at docks.

🔧 In busy ports, the crane adjusts position based on ship size. The grab moves along the bridge and drops into cargo holds. Multiple cranes can be scheduled via port systems for faster operation.

MSW Handling: Grabs household waste at waste-to-energy plants.

Recyclables: Sorts metal, plastic, and paper in recycling facilities.

Ore Transport: Picks up limestone, iron ore, bauxite at open-pit and underground mines.

Coal Stockpiles: Moves coal to crushers or storage yards.

💡 During mining, the crane shifts materials between workshops, reducing downtime.

Bulk Chemicals: Lifts sulfur, petroleum coke, fertilizers in plants.

Biomass Fuels: Transfers wood chips, pellets in power stations.

Cement, Clinker: Moves raw materials in cement plants.

Debris Removal: Clears demolition waste like bricks and concrete blocks.

🚧 On construction sites, it feeds sand to mixers or lifts rubble into trucks—safer and faster than manual work.

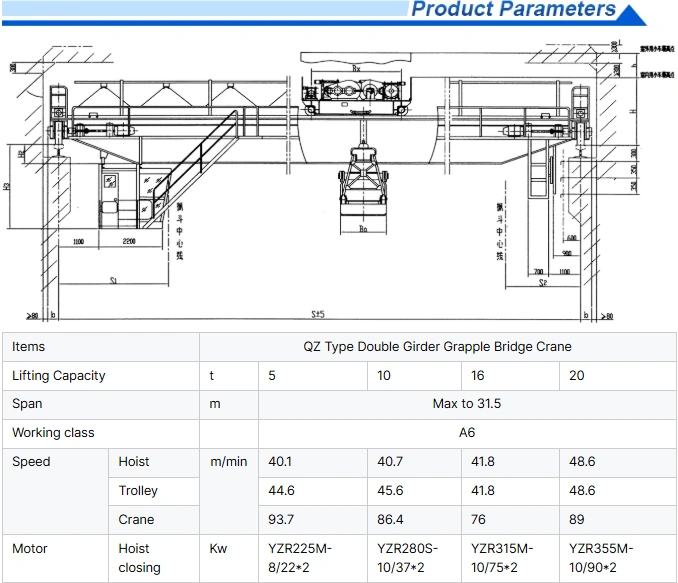

Rated Load: 5–50 tons (includes grab weight)

Span: 10.5m–31.5m

Working Class: A6–A8 heavy duty

Temperature Range: -20℃ to +40℃

Grab Type: Four-rope double-drum grab; opens/closes at any height

Installation: Fixed indoor/outdoor bridge with optional rain cover

Operation: Driver’s cabin or wireless remote

Customization: Track width, grab type, and operation mode available on request

📝 Note: For underwater or special materials, please request custom grabs when ordering.

✅ Smart & Automated – PLC and remote control for hands-free operation

✅ Durable & Reliable – Works in extreme heat, humidity, or dust

✅ Efficient Handling – Fast load/unload for higher productivity

✅ Eco-Friendly Upgrade – Used in sustainable industrial transitions

Confirm parameters: lifting capacity, span, height, working duty, rail type, cab access, grab type.

Outdoor use must include a rain cover (adds ~5% weight/load).

Two grab opening directions:

• Type I: parallel to crane travel

• Type II: parallel to trolley travel (must be specified in contract)

✔ Power plants

✔ Metal recycling yards

✔ Cement factories

✔ Docks and terminals

✔ Mining operations

✔ Waste plants

🛠 QZ cranes are semi-custom machines. We tailor each one to your project. For non-standard conditions, contact us for special design options.

Wechat:

+86 16627702870