- A3

- A4

-

Lifting hook

Lifting hook

Lifting hook

Lifting hook

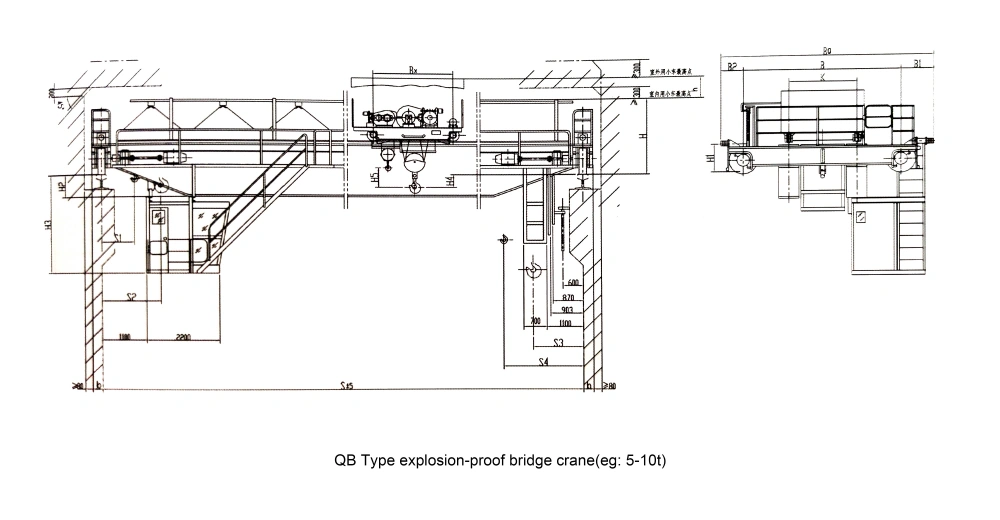

Our company produces the only certified clean explosion-proof fully automatic crane in China, holding 16 authorized patents. It is the only company with a production qualification for such cranes. The crane features advanced technologies, including:

High-seal explosion-proof drive mechanism

Self-lubricating bearings for maintenance-free operation

Compact design integrating motors, reducers, brakes, and electrical monitoring systems.

The new double-hoist explosion-proof crane, one of the largest in China, is widely used in the aerospace industry. It consists of two 160-ton hoist units, a heavy-duty bridge frame, and a three-in-one drive. The double hoists can lift and lower in sync, enabling simultaneous lifting and workpiece rotation. Its explosion-proof rating is DIICT4, and it complies with both GB National Standards and FEM European Standards. The crane uses hard-tooth surface reducers, variable frequency drives, and multiple safety protections. It is designed for high efficiency, low energy consumption, and minimal environmental impact.

This crane can be used in any hazardous environment requiring explosion-proof or other high-safety features. It is commonly applied in water, chemical, oil, gas, pharmaceutical, and food industries.

The explosion-proof crane is made from special materials and structures that effectively prevent static electricity, sparks, and other factors that could lead to explosions.

LDC低净空单梁桥式起重机

Double Girder Explosion-Proof Bridge Crane – Key Benefits and Features

Certified Explosion-Proof Safety for Hazardous Areas

Meets Strict Standards:

Complies with GB3836.1/GB3836.2 (Explosion-Proof Electric Equipment) and JB/T5897 (Explosion-Proof Crane Standards).

Certified for Exd II BT4 and Exd II CT4, making it suitable for Zone 1 & Zone 2 hazardous environments (flammable gases/steam mixtures).

Government-Certified Testing:

Approved by authorized explosion-proof testing agencies.

Durable Electrical & Mechanical Design

High Protection Rating:

IP55-rated enclosures protect electrical parts from dust and water.

Premium Motors & Insulation:

Class F insulation with a temperature rise of Class B, ensuring long-lasting performance in harsh conditions.

Overload & Thermal Protection:

Includes an electronic overload limiter and warning horn, plus PTC thermistors for thermal protection.

Smooth & Precise Operation

Advanced Motion Control:

Features two-speed hoisting and inverter-controlled trolley/bridge travel for smooth, jerk-free movements.

Low Noise Operation:

Runs at under 85 dB(A) at full load, reducing noise pollution in the workplace.

Fail-Safe Safety Mechanisms

Emergency Braking System:

Automatic brake activation during power failure with asbestos-free lining.

Comprehensive Safety Features:

Includes overload limiter, dual limit switches (lifting/traveling), interlock protection, buffers, anti-collision systems, and emergency stop.

Complies with International Crane Standards

Design & Safety Regulations:

Follows GB/T3811-2008 (Crane Design Rules), GB6067.1-2010 (Lifting Equipment Safety), and JB/T10219-2011 (Explosion-Proof Beam Cranes).

Flexible Control Options

Ground or Cabin Operation:

Can be controlled from the ground via remote or pendant, with an optional driver's cabin for high-precision tasks.

Why Choose This Explosion-Proof Crane?

Reliable in Extreme Environments: Ideal for chemical plants, oil refineries, and gas facilities.

Longer Lifespan: Made with high-quality materials and thermal protection to reduce wear.

Regulatory Compliance: Fully certified for use in explosive environments.

This explosion-proof overhead crane is designed for environments with a risk of flammable gases, vapors, or combustible dust. It is perfect for industries needing ATEX/GB3836-compliant lifting solutions and comes with Exd II BT4/CT4 certification.

Perfect for:

Petrochemical, pharmaceutical, mining, and other industries at risk of flammable gases or dust.

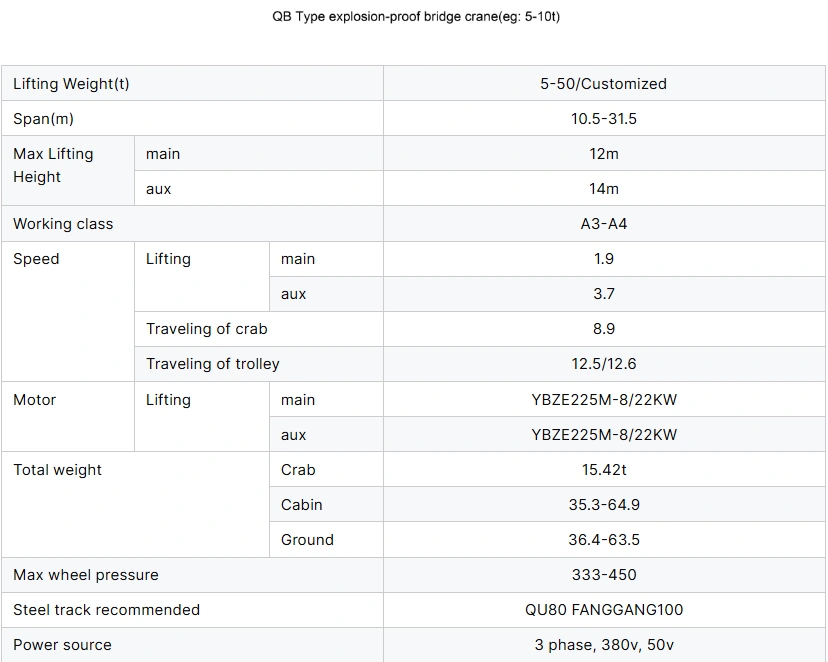

The QB explosion-proof bridge crane meets the GB3836.1-2010 and GB3836.2-2010 standards, as well as IEC79-1, BS4683, and EN50018 regulations. It is designed for use in coal mines with methane explosive environments, operating at temperatures from -20°C to +40°C, with a relative humidity of up to 85% at 25°C. The equipment is safe for use up to an altitude of 1000 meters and complies with coal mine safety regulations. Surface temperatures of electrical components are limited to 150°C when coal dust may accumulate, or 450°C when dust accumulation is prevented through sealing or ventilation.

Oil & Gas Industry:

Ideal for oil refineries, drilling platforms, and storage facilities dealing with explosive hydrocarbons, as well as gas processing plants exposed to methane, propane, or butane.

Petrochemical & Chemical Plants:

Perfect for handling flammable solvents, such as benzene, ethanol, or ammonia. It is also suitable for paint and coating manufacturing where explosive vapors are present.

Pharmaceutical & Chemical Storage:

Safe material handling in solvent-based drug production and warehouses storing flammable chemicals (Zone 1 & Zone 2).

Power Generation (Gas & Biofuel Plants):

Suitable for maintenance and fuel handling in gas turbine facilities and biogas plants with methane-rich environments.

Mining & Coal Processing:

Used in underground mines with flammable dust (coal, sulfur, metal powders) and coal preparation plants with explosive particulate risks.

Aerospace & Defense:

Designed for handling rocket fuels, propellants, and munitions in controlled environments.

Stainless Steel/Nylon Wheels:

Prevents sparking from friction.

Flame-Proof Electrical Components:

Motors, switches, and controls comply with GB3836/IECEx standards.

Thermal & Overload Protection:

Prevents overheating and ensures safety in high-risk areas.

Any Zone 1 or Zone 2 environment with Group IIB/IIC gases and T4 ignition temperature hazards.

Wechat:

+86 16627702870