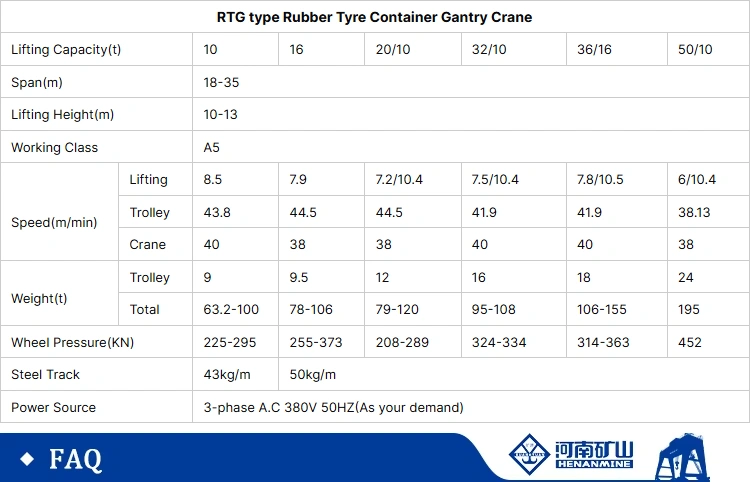

- A6

- A7

-

Lifting hook

Lifting hook

Lifting hook

Lifting hook

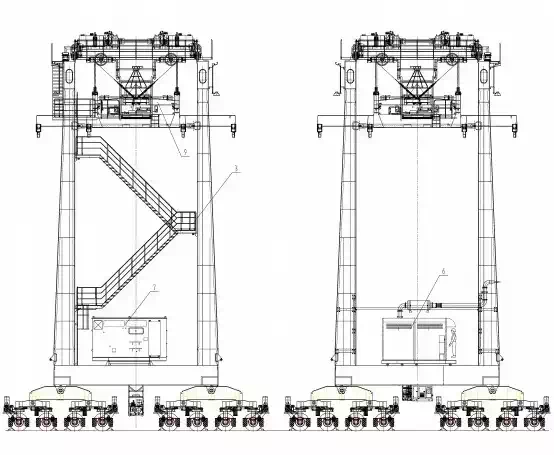

Drawing trolley structure ensures a lightweight frame without compromising strength.

Box-type welded steel (Q235B/Q345B) offers durability for heavy-duty container handling.

Rubber-tired mobility enables flexible movement across uneven ground (gradient tolerance: <1–3%).

Separate drive mechanisms and frequency-controlled travel ensure smooth operation.

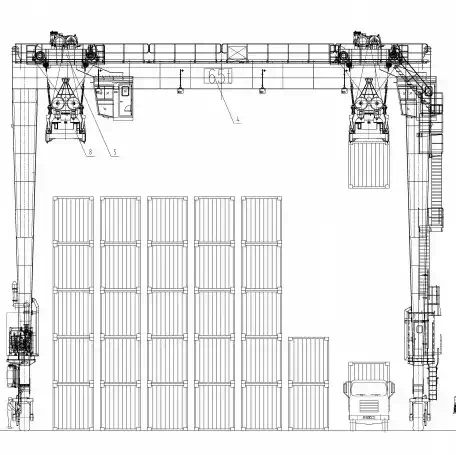

High-precision container spreader handles ISO standard containers (option for twin-lift).

Primary power: Cable drum/slide wire (380V, 50Hz AC).

Backup diesel generator for power outages or yard transfers, maximizing uptime.

Schneider/Siemens PLC + variable frequency drives for precision speed regulation.

Remote Monitoring (RCMS) enables real-time diagnostics and remote operation.

F-class insulated motors (Jiamusi, ABM, or SEW) ensure reliability in harsh conditions (-20°C to +45°C).

Vacuum-cast wheels: Low maintenance, high transmission efficiency.

Forged steel hooks and top-tier lifting winches (A6-A7 duty class).

Abrasion-resistant rubber tires with protection devices for longevity.

Wind-resistant: Operational up to 20 m/s; withstands 44 m/s when parked.

Humidity-tolerant (up to 95% with dew).

Custom designs available for specialized requirements.

Reduced downtime with dual power systems.

Energy-efficient drives lower operational costs.

Modular design simplifies maintenance and part replacement.

✅ Proven durability – Meets ISO, FEM, and DIN standards.

✅ Smart automation – PLC controls + remote monitoring.

✅ Versatile configurations – Capacity and span tailored to your needs.

✅ Global component quality – Siemens, Schneider, SEW, and premium Chinese brands.

Ideal for: Ports, intermodal yards, and logistics hubs requiring high mobility, reliability, and ROI.

Primary Use: Stacking, loading, and unloading ISO standard containers in busy port yards.

Advantage: Rubber tires enable flexible movement between stacks without rail restrictions.

Rail-to-Truck Transfer: Efficiently shifts containers between trains and trucks.

Cross-Docking: Accelerates cargo flow in distribution centers with high-duty cycle (A6-A7) performance.

Dense Stacking: Handles 1-over-3 or 1-over-4 container rows, optimizing yard space.

All-Weather Operation: Functions in temperatures from -20°C to +45°C and high humidity.

Backup Power Reliability: Diesel generator ensures uninterrupted work during power outages.

Uneven Ground Adaptability: Tolerates floor gradients up to 3% (with partial slopes).

Heavy Cargo Handling: Transports oversized containers for automotive, steel, or machinery sectors.

Custom Configurations: Optional twin-lift spreaders for tandem container moves.

No Fixed Infrastructure: Ideal for pop-up logistics sites or emergency cargo staging.

Quick Relocation: Self-propelled tires allow easy transfer between work zones.

✔ Mobility: Rubber tires outperform rail-bound cranes in dynamic environments.

✔ Dual-Power Flexibility: Cable/diesel options suit grids or remote areas.

✔ Automation-Ready: Siemens PLC and RCMS support future smart port integration.

Target Industries: Port authorities, logistics firms, freight operators, and industrial manufacturers.

Wechat:

+86 16627702870