- A5

-

Lifting hook

Lifting hook

Lifting hook

Lifting hook

Low Headroom Electric Single Girder Crane

The LDC low headroom electric single girder crane consists of a box-type main beam, end beams, trolley, and operating mechanism. The electric hoist is placed on one side of the main beam to maximize hook clearance, reducing the height and cost of the factory building.

The main beam is designed in a box structure, with offset rails and horizontal wheels for stability and safety. It also prevents wheel wear on the track. The running motor can be equipped with soft start or variable frequency drive, ensuring smooth startup and safe operation.

The crane can be operated via a ground handle, wireless remote, or operator cabin. The working class is A3, and it operates in temperatures ranging from -25°C to +40°C.

Features

Wide trolley wheelbase for smooth operation

Compact design with good rigidity

Low noise and sensitive operation

Safe, reliable, and attractive design

Applications

This low headroom crane is commonly used in factories with limited ceiling height, such as mechanical manufacturing, assembly, and warehouses. It’s designed to maximize lifting height while reducing building costs, based on European crane technology. The crane features a welded box-type main beam made from steel plates, with the hoist running on a 16Mn flange. It is trusted by many customers for its durability and efficiency.

Low Headroom Single Girder Overhead Crane – Key Advantages & Features

1. Space-Saving Design for Maximum Efficiency

Designed for low headroom applications, this crane optimizes vertical space by minimizing the distance between the hook and the ceiling. It’s perfect for factories, warehouses, and workshops with limited ceiling height, keeping operations smooth in tight spaces.

2. Durable Construction & High-Performance Components

The crane features a single girder made from high-strength steel plates (16Mn flange), ensuring strong load-bearing capacity and long-lasting durability. The electric hoist runs along the lower girder flange, boosting lifting efficiency while keeping the crane slim.

Customizable spans fit different facility layouts, making this crane versatile.

3. Advanced Engineering for Better Performance

The crane is treated with medium-frequency quenching to enhance its rigidity, toughness, and resistance to fatigue. Shot-blasting treatment on all metal parts increases surface hardness and protects against corrosion, extending the crane’s lifespan.

4. Top-Notch Safety Features for Reliable Operation

Overload protection safeguards the crane from damage due to excessive loads.

The emergency brake system ensures quick stopping in urgent situations.

Rubber buffers absorb shocks, reducing wear on the crane and improving safety.

5. Flexible Configurations for Various Needs

This crane is available in both low headroom hoist and trolley crane designs to meet different lifting needs.

High-quality motors (from Chinese or international brands) provide smooth, energy-efficient operation.

Choose from optional control methods: cabin control or handheld remote.

Why Choose This Low Headroom Overhead Crane?

✅ Compact yet powerful – Ideal for spaces with limited height.

✅ Customizable – Tailor the span, lifting capacity, and control options to your needs.

✅ Built to last – Steel processing and safety systems ensure long-term reliability.

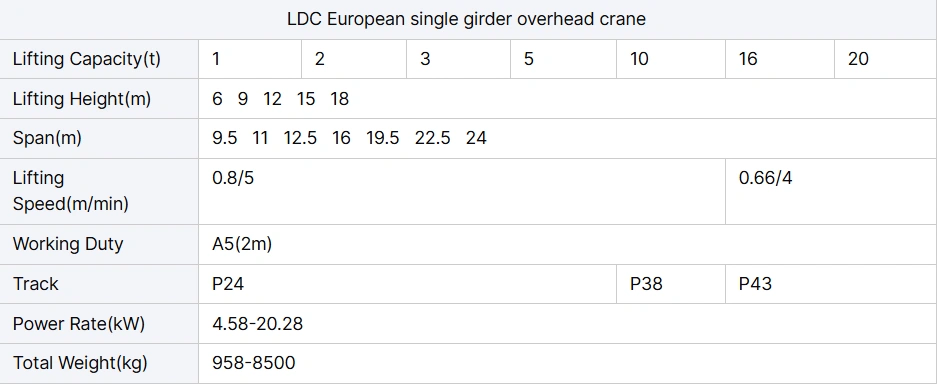

LDC European Standard Electric Single Girder Overhead Crane

The LDC European-style crane works with the HDHa European electric hoist. It integrates advanced foreign technology, optimizing design for better performance and reliability. The modular design, combined with modern computer technology, enhances crane efficiency, reliability, and energy savings.

Lightweight & Efficient – Using our in-house design software and advanced 3D modeling, we achieve an optimized structure. The crane’s use of high-strength materials reduces weight while increasing load capacity. Compared to traditional cranes, this crane is lighter and has lower wheel pressure.

Compact & Space-Efficient – The crane’s small hook-to-side distance and low height above the track allow for maximum use of limited workspace. This reduces building costs and saves valuable factory space.

Low Operating & Maintenance Costs – The reduced wheel pressure and compact design minimize initial construction costs. Reliable performance and high-quality components reduce the need for maintenance and lower overall operational expenses.

High Performance – The crane uses variable frequency technology for smooth operation. Heavy loads move slowly while light loads are handled quickly. With anti-sway technology, the crane ensures precise positioning and minimal impact on the facility.

Quality Standards – Designed, manufactured, and inspected according to the latest national and international standards, including FEM, DIN, and IEC.

Advantages of the LDC European Crane

Lightweight – Compared to the older LDA models, the LDC crane is 15-30% lighter, with reduced wheel pressure (10-35%). This minimizes the structural demands on buildings, saving on construction costs.

Precision Components – The crane uses high-precision gears, hard-tooth reducers, steel drum structures, and forged wheels, all powered by a variable frequency system.

Energy-Efficient – The crane is lightweight, low-energy, and features compact dimensions, providing a cost-effective, high-performance solution.

The Low Headroom Single Girder Overhead Crane is designed for workshops with limited vertical space but high lifting needs. Its compact electric hoist system increases the lifting height, making it perfect for industries with low ceiling clearance.

Key Applications

✅ General Machinery Manufacturing – Handles assembly, material handling, and positioning in workshops with low ceilings.

✅ Warehousing & Logistics – Maximizes space in tight warehouses, enabling efficient loading and unloading of goods.

✅ Automotive & Assembly Lines – Supports precise part movement in assembly areas with limited height.

✅ Steel & Metal Fabrication – Lifts heavy materials like steel coils and beams in confined spaces.

✅ Textile & Paper Mills – Works in low-roof facilities with limited overhead space.

✅ Power Plants & Maintenance Facilities – Ideal for equipment installation and repairs in areas with low clearance.

Why Choose This Crane for Low-Clearance Workspaces?

Saves Vertical Space – The low headroom design allows for greater lifting heights in areas with low ceilings.

Versatile & Adaptable – Suitable for light to medium-duty lifting in various industries.

Reliable & Safe – Built-in overload protection, emergency brakes, and shock-absorbing buffers ensure safe and secure operation.

This crane is the ideal lifting solution for industries where every inch of vertical space matters, offering power, precision, and space efficiency.

Wechat:

+86 16627702870