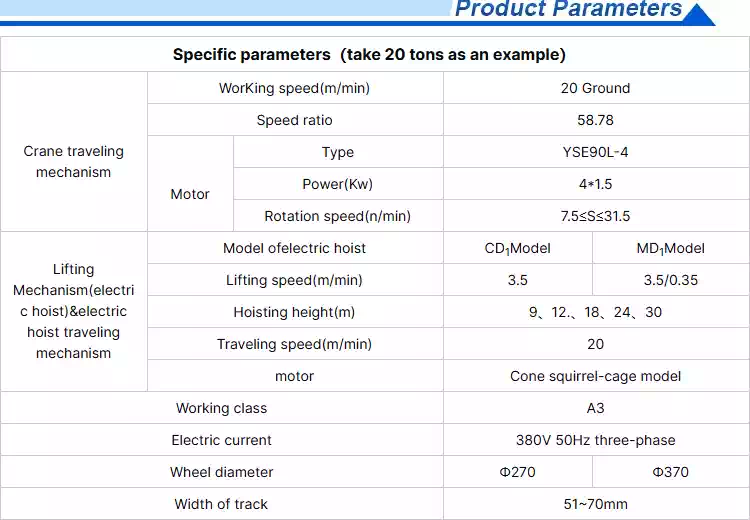

- A3

- A4

- A5

-

Lifting hook

Lifting hook

Lifting hook

Lifting hook

High-Strength Material: Uses Q235 steel and I-steel for long-lasting performance.

Sand-Blasted Rust Removal: Prevents corrosion for better durability.

One-Piece Box Girder: No welding means stronger structure and less maintenance.

Vacuum-Cast Wheels: Treated for wear resistance.

Kuangyuan Soft-Start Motors: Provides smooth movement (customizable).

Schneider Electrical Parts: Reliable, certified components for steady performance.

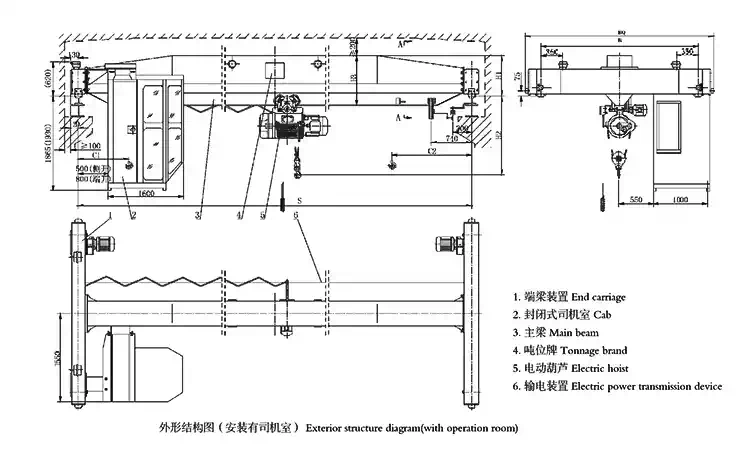

Two Control Modes: Ground (pendant) or cabin (open/closed, left/right options).

Flexible Entry: Side or end gate access to fit different workspaces.

Overload Protection: Stops damage from heavy loads.

Limit Switches: Prevents collisions during travel and lifting.

Emergency Stop + Voltage/Current Protection: Ensures safe shutdown.

Polyurethane Buffers: Reduces impact for smoother stops.

Adjustable lifting capacity (1–32 tons).

Custom span, height, and voltage (e.g., 220V–480V).

Rail type and length to fit your needs.

Special designs for harsh environments (heat, corrosion, etc.).

1-Year Warranty: Free fixes for manufacturing issues.

Lifetime Spare Parts: Low-cost replacements after warranty.

Technical Support: Help with setup and maintenance.

✅ Saves Money: Lighter design cuts installation and energy costs.

✅ Easy to Fix: Simple modular design for quick repairs.

✅ Space-Saving: Works well in tight spaces.

✅ Meets Global Standards: Follows ISO, FEM, and CE safety rules.

A single girder overhead crane is a lifting device installed in workshops, warehouses, and storage yards. Its two ends sit on tall concrete columns or metal supports, forming a bridge-like structure. The crane moves along tracks on elevated rails, using the space below to transport materials without blocking ground equipment. It is the most widely used lifting machine in modern industry, essential for mechanized and automated production.

These cranes are used in factories, steel plants, chemical facilities, railways, ports, and logistics centers.

The LDA electric single girder crane works with CD/MD-type electric hoists. It is a lightweight, rail-mounted crane, popular in machinery manufacturing, assembly lines, and warehouses. Most models use ground controls and can be paired with CD1/MD1 hoists. Key features include compact size, smooth operation, and multiple specifications.

This crane is built for safe and efficient material handling in industries like:

Assembly Lines: Move heavy parts during production.

Machining Workshops: Transport steel, machinery parts, and raw materials.

Automotive Industry: Lift engines, chassis, and large components.

Loading/Unloading: Handle pallets, containers, and packaged goods.

Storage Management: Organize heavy items in high racks.

Steel & Metal Industries: Carry coils, sheets, and metal bars.

Timber & Construction: Hoist lumber, cement blocks, and prefab structures.

Maintenance Work: Install or repair turbines, generators, and transformers.

Dry Storage Areas: Move bulk ingredients like sacks and barrels.

⚠ Do Not Use In:

Explosive areas (chemical plants, fuel storage).

Highly corrosive conditions (acid/alkaline exposure).

Always display the crane’s max load capacity on a visible sign.

Never stand on the crane or use it to lift people.

Only trained operators can use the crane. No alcohol allowed.

Stay focused during operation. No talking, smoking, or distractions.

Keep the crane clean. No tools, flammable items, or hazards on it.

Never exceed the crane’s weight limit.

Do Not Lift If:

Loads are unsecured.

Overweight.

Signals are unclear.

Loads are slanted, buried, or frozen.

People are on the load.

Unsafe materials (flammables, explosives, liquids).

Damaged wires or faulty hoist.

Keep loads 2m above ground during normal operation. Clear obstacles by 0.5m.

For loads under 50% capacity, two motions can work together. For over 50%, use one motion at a time.

Do not raise/lower main and auxiliary hooks together (unless specified).

Never weld, hammer, or work under a lifted load (unless supported).

Power off and tag the switch before repairs. Live work needs safety measures and supervision.

Never throw objects from the crane.

Check limit switches and safety devices regularly.

Never use limit switches as a stop method.

Do not lift if the brake is faulty.

Never move loads over people or equipment.

Use a separate ground wire for welding—never the crane body.

Keep at least two rope loops on the drum when the hook is at its lowest.

Do not crash cranes or push another crane with one.

Test brakes by lifting 100–200mm for heavy, explosive, or liquid loads.

Use under 36V lights for inspections.

Ground all electrical parts. Resistance must be below 4Ω.

Perform regular safety checks and maintenance.

Wechat:

+86 16627702870