- A3

- A4

-

Lifting hook

Lifting hook

Lifting hook

Lifting hook

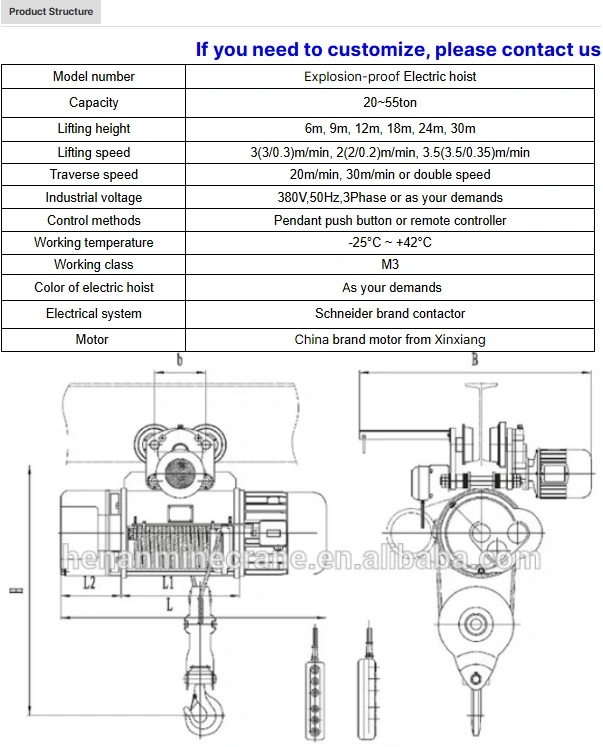

Our explosion-proof hoist is designed to meet Chinese safety standards for hazardous areas. Its "flameproof" design uses spark-free materials for reliable safety. It’s small, lightweight, but lifts heavy loads easily.

Main Parts:

Lifting System: Motor, gearbox, drum, hook.

Movement System: Motorized trolley, wheels, gears.

Electrical System: Control box, buttons, wires, safety switches.

Key Features:

Easy to fix – parts can be replaced fast.

Explosion-proof motor and control box. Buttons and switches meet safety rules.

Many parts work with other models.

Standard gear design for simple repairs.

Why It’s Important:

This hoist is made for flammable places like oil, chemicals, or mines. It’s safe, strong, and saves energy. The motor and controls are sealed to stop sparks. It’s simple to use and lasts long.

How It Works:

Like a regular hoist but safer. The motor turns the drum to lift items. Special materials and design prevent fires or explosions.

Real-World Use:

In risky places (e.g., oil rigs, factories), this hoist lifts safely without sparks. It’s stable in heat, cold, or wet conditions. Workers control it remotely for extra safety.

Key Advantages of Explosion-Proof Electric Hoist – Safe & Efficient Lifting for Hazardous Environments

Saves space but stays strong.

Stable even at full load due to smart design.

Regular speed for daily tasks.

Slow speed for precise work like:

Machine repairs

Mold handling

Fragile cargo

More versatile than single-speed (CD1) models.

Lifts large loads for tough jobs.

Strong parts handle extreme weight.

Safe for flammable places (chemical, oil, gas, mining).

Spark-proof parts:

Aluminum/beryllium bronze rope (no sparks).

H62 copper alloy housing (rust-proof, fire-safe).

Hardened gears for long life.

Motor: Taper brake motor (Nanjing Special Motor) – 3x power, handles frequent starts.

Gearbox: Hardened gears + ball bearings for smooth movement.

Rope: Export-grade steel, 6x safety, anti-slip drum.

Hook: Tested at 150% load, thick pulley for durability.

Quick to take apart: Gearbox, motor, drum, and controls can be fixed separately – less downtime.

Weight: Up to 20+ tons.

Height: 30m–100m+.

Choices: Single/double drum, two hooks, voltage options (380V/36V/24V).

Oil & Chemicals: Lifting equipment safely in flammable areas.

Pharmaceuticals: Moving materials in production lines.

Military: Assembling and repairing weapons safely.

Industries: Oil, chemical plants, mines, gas production, grain processing.

Environments: Places with explosive dust or gases (ATEX/IECEx certified).

Safety: No sparks – safe in flammable areas.

Fits On:

Single-girder cranes

Bridge/gantry cranes

Jib cranes (small changes needed)

Winches

Common Uses:

Factories: Moving machines, assembly lines.

Warehouses: Loading/unloading goods.

Ports: Stacking cargo, container yards.

Mines: Equipment repairs, material transport.

MD1 Bonus: Two speeds – fast for normal work, slow for precise tasks.

Best For:

Oil & gas: Refineries, fuel storage.

Chemical plants: Flammable liquids/powders.

Pharmaceuticals: Alcohol production zones.

Power plants: Coal dust areas.

Special Features:

Works with explosion-proof trolleys.

Copper alloy parts – no sparks.

Used In:

Steel mills: Moving hot metal.

Shipyards: Lifting engine parts.

Construction: Handling concrete blocks.

Height: Up to 100m (for deep mines/silos).

Double Hooks: For heavy, balanced loads.

Voltage: 24V/36V/380V – works worldwide.

Check Often: Test motors, wires, hooks, and controls.

Keep Clean: Remove dirt and oil for better cooling.

Add Oil: Lubricate bearings and chains to reduce wear.

Test Safety: Ensure emergency brakes and limit switches work.

Prevents explosions in risky places like oil refineries.

Saves lives and reduces costly accidents.

Makes work faster and easier.

Train workers to use it correctly.

Pick the right model for your workplace.

Wechat:

+86 16627702870