- M3

- M4

- M5

-

Lifting hook

Lifting hook

Lifting hook

Lifting hook

An electric hoist (electric block) is a lifting device installed on cranes or gantries. It combines mechanical and electrical systems, with types like high-speed or ultra-high-lift hoists. Key features include compact size, light weight, and easy operation, making it ideal for factories, warehouses, and docks.

How it works: Powered by sliding lines, it uses a control box to manage lifting/walking motors for precise load handling. Most are operated via ground buttons, remote control, or cabin controls.

Motor: Powers the hoist (converts electricity to motion).

Reducer: Slows motor speed to increase torque.

Brake: Ensures safe stopping/descending.

Chain/Wire Rope: Lifts loads (chain for chain hoists, rope for wire hoists).

Hook: High-strength, heat-treated for load security.

Safety features: Limit switches, 24V/36V transformers, and anti-drop hooks.

Brakes: Must stop loads without slipping.

Limit switches: Hook height/travel limits must work.

Motor: No abnormal noise; synchronized movement.

Controls: Buttons/remote must respond; no damage.

Rope/Chain: No breaks/kinks; proper lubrication.

Hook bolts/insurance pins: No cracks or looseness.

Trusted globally for safety, compactness, and adaptability.

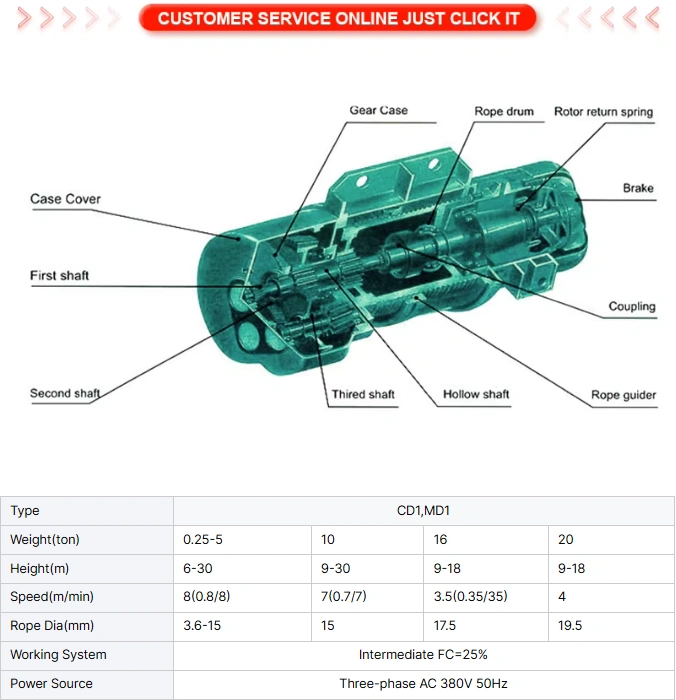

Precision (MD model) or simplicity (CD1 model).

Scalable from light (0.25t) to heavy loads (32t).

Space-saving: Small but powerful, perfect for workshops, factories, and construction sites.

Boosts productivity: Improves work efficiency and ergonomics.

CD1 Model: Single speed for standard lifting.

MD Model: Dual speed (normal + low) for precise tasks like machine maintenance or delicate loads.

Expanded capacity: HC 20t model for heavier loads.

Strong lifting power: Robust wire rope handles stress reliably.

Built-in protections: Overload protection, thermal-safe motors, and emergency stop switches.

Secure hooks: Latched hooks with rubber buffers for stability.

Pre-tested: All parts and final products are factory-tested and certified.

Stationary (A1-A4): Fixed in multiple positions (up/down/left/right).

Crab-style: Moves along tracks for flexible workspace use.

Easy repairs: Common spare parts reduce downtime.

Long lifespan: Corrosion-resistant paint (custom colors, ~100μm thick).

Industries: Warehousing, manufacturing, assembly lines, and repairs.

Environment: Works in non-explosive, non-corrosive areas (-20°C to +40°C, ≤85% humidity).

Load range: 0.25t–32t with 3m–30m lifting height.

Non-standard designs: Custom hoists for special needs.

Certified safety: Meets Chinese GB/T crane standards.

Rigorous testing: Pre-assembled and inspected before delivery.

Easy to use: Simple controls for smooth operation.

Cost-effective: Low maintenance and energy-efficient motors.

Factories & Workshops: Used for assembly lines, machine maintenance, and moving materials.

Heavy Industries: Lifts raw materials, tools, and finished goods in steel plants, foundries, and automotive factories.

Storage Warehouses: Moves heavy pallets and crates.

Distribution Centers: Loads/unloads trucks precisely (MD model’s low-speed option).

Building Sites: Lifts steel beams, concrete blocks, and other materials.

Bridge/Gantry Cranes: Mounts on overhead tracks for flexible use.

Docks & Wharves: Loads/unloads cargo from ships and containers.

Freight Yards: Handles bulky items with crab-style hoists on rails.

Mining Operations: Transports ores and equipment in tough conditions (corrosion-resistant models).

Large Retail Stores: Moves stock or heavy displays (compact CD1 model).

Machine Shops: MD model’s low-speed mode ensures safe equipment repairs.

Vehicle Garages: Lifts engines or heavy parts.

Barns & Sheds: Hoists feed bags, machinery, or harvests.

Winches: Modified for pulling/towing in salvage operations.

Special Setups: Custom hoists for tight spaces or unique angles.

(Electric Hoist) is a compact, easy-to-use lifting device for factories, warehouses, and docks. It works by powering motors to lift loads via wire ropes or chains.

Wear protective gear.

Check operator certification: 5t+ hoists require a ground operation license.

Inspect all safety devices. Test run to confirm normal operation.

Secure loose items on loads. Check surroundings.

Never use hooks with broken anti-drop devices.

Keep control buttons responsive. Ensure secondary steel cables and hook safety work.

Lift loads vertically. Never exceed 150cm height or swing over people.

No overloading. Stay clear of moving ropes.

For emergencies (e.g., load slipping), lower loads to empty areas.

Park hoist in designated area. Raise hooks 180cm+ to avoid collisions. Turn off power.

Log equipment checks.

Quality checks:

Test load capacity (≥1.25x rated weight).

Lift height ≥30cm.

Current ≤1.68A.

Motors must start at low voltage (small: 300V; large: 280V).

Noise limits: small motor ≤85dB; large motor ≤65dB.

Inspect chains for length/alignment.

Check for damage or dirt.

No power: Check voltage, replace fuses, or fix wiring.

Motor won’t start: Adjust voltage, fix phase loss, or clean rusted brake discs.

Unstoppable motion: Repair stuck buttons/contacts.

Slipping brakes: Tighten nuts or replace oily/worn brake rings.

Slow motor/overheating: Adjust axle clearance or rewind coils.

Electric shocks: Ground the or fix insulation.

Wechat:

+86 16627702870