- M3

- M4

- M5

- M6

-

Lifting hook

Lifting hook

Lifting hook

Lifting hook

Operation:

Drum rotation reaches 1.25× normal speed.

Centrifugal force engages mechanical stop.

Normally inactive during regular use.

Activates automatically if primary brake fails:

Safety switch prevents lowering operation.

Emergency Lowering Procedure:

Use "UP" command to reset brake.

Repeat as needed for controlled descent.

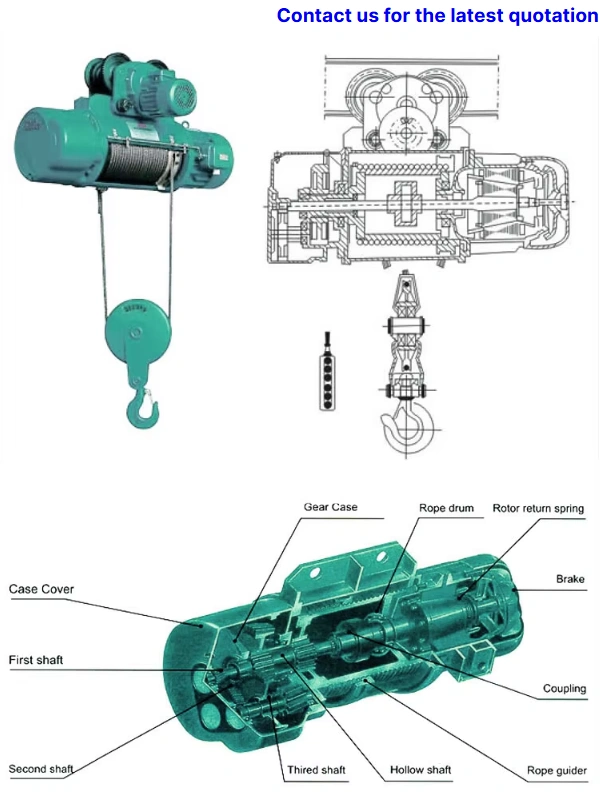

Drum

Friction brake pad

Ratchet wheel

Cam

Adjustment bolt

Pawl

Fixed pin shaft

Spring mechanism

Limit switch

External hoist housing

Environment: Non-explosive, non-corrosive areas only.

Dual Brake Rule: Both braking systems must remain operational.

Main Systems: Lifting mechanism, travel system, controls, and backup brake.

Motor: YZD series with dual braking (primary + safety).

Thermal Protection: Integrated heat shield.

Rope: Steel-core construction for heat resistance.

Safety Limits:

Overload cutoff at 105% capacity.

Dual-height limit switches.

Operating Conditions:

Temperature: ≤60°C

Altitude: ≤1000m

Prohibited: Flammable/explosive atmospheres.

Capacity: 0.5–20 tons.

Lifting Height: 6–30m.

Speed: 7–8m/min.

Primary Use: Molten metal handling (excludes acidic/explosive environments).

Mounting Options: Compatible with LDY single girders or fixed tracks.

Safety Features: Dual brakes, dual limit switches, heat shield.

Compliance: Meets international and specialized metallurgical standards.

✔ Extreme Heat Resistance – Engineered for molten metal applications.

✔ Controlled Operation – Dual-speed precision for varied tasks.

✔ Fail-Safe Protection – Redundant braking and safety systems.

✔ Global Approval – Certified for industrial use worldwide.

Dual-Speed Operation: Normal and slow modes for delicate tasks like sandbox molding and machine maintenance.

Wide Application: Designed for steel mills and foundries handling molten metal, hot solids, and non-metallic materials.

Thermal Protection: Insulated main beam operates reliably at 40°C (≤50% humidity).

High-Temperature Design: Reinforced components withstand molten metal lifting.

Robot-Welded Steel Beam: Single-piece construction for maximum strength.

Sandblasted Finish: Enhanced paint adhesion prevents corrosion.

6-Directional Movement: Maximizes workspace coverage.

Protection Systems: Includes overload cutoff, emergency stop, and optional explosion-proof/acid-proof versions.

Control Choices: Pendant, remote, or cabin (joystick) operation.

Attachment Compatibility: Works with slings, clamps, magnets, and other tools.

Global Standards: CE, SGS, ISO 9001/14001/28001 certified.

Full Service: Custom engineering, installation, and technician training.

Made for steel mills and foundries

Handles molten metal safely

Works in high heat up to 60°C

Two braking systems for safety

Heat protection on all parts

Can lift 0.5 to 20 tons

Works from 6m to 30m high

Moves at 7-8 meters per minute

Steel Plants

Moves hot metal safely

Works with ladles and castings

Construction Sites

Lifts steel beams

Moves concrete blocks

Machine Shops

Repairs heavy equipment

Two speeds for careful work

Factories

Handles heavy parts

Moves big molds

Farms

Lifts feed bags

Moves farm machines

Building Projects

Works on bridges

Helps with tall buildings

Mines & Power Plants

Tough for hard conditions

Moves heavy loads

Two Brakes: Main brake plus backup

Heat Shield: Blocks hot metal heat

Safe Rope: Steel core handles heat

Weight Limit: Stops at 105% load

Height Stops: Two safety switches

Motor Protection: H-class insulation

Normal work uses main brake

If main brake fails:

Drum spins faster

Backup brake stops it

Power cuts off automatically

To lower safely:

Press "up" to reset

Repeat as needed

Never use with only one brake

Keep away from:

Explosive areas

Acid fumes

Flammable gas

Temperature range: -10°C to +60°C

Max height: 1000m above sea level

Needs 380V power

Lets workers stand far away

Safer near hot metal

Better than hand controls

Moves with the worker

Motor: Special H-class

Brakes: Two systems

Rope: Steel inside

Safety: Meets strict rules

Made under Chinese safety standard [2007] No.375

Wechat:

+86 16627702870